Enhancing Appeal and Quality: Zunhao’s Distinctive Packaging Solutions

In addition to ensuring the quality of our packaging pouches and bags, they must also be visually appealing. At Zunhao, our bags and pouches boast the following distinct characteristics:

- Customizable sizes and features to suit your specific needs

- Constructed from laminated materials for excellent barrier protection

- Cost-effective and FDA approved for safety and compliance

- Lightweight design reduces transportation costs

- Reliable with a guaranteed shelf life of 2 years

Navigating artwork preparation for packaging pouches can be a daunting task for marketers, packaging experts, and even end-users. There’s nothing more frustrating than receiving pouches that don’t match your expectations.

To ensure your complete satisfaction, we ask that you provide us with an artwork and design outline upfront. We’ll review it, make any necessary corrections or recommendations, and send it back to you for approval. Once you’re happy with the design, Zunhao will proceed with our manufacturing process.

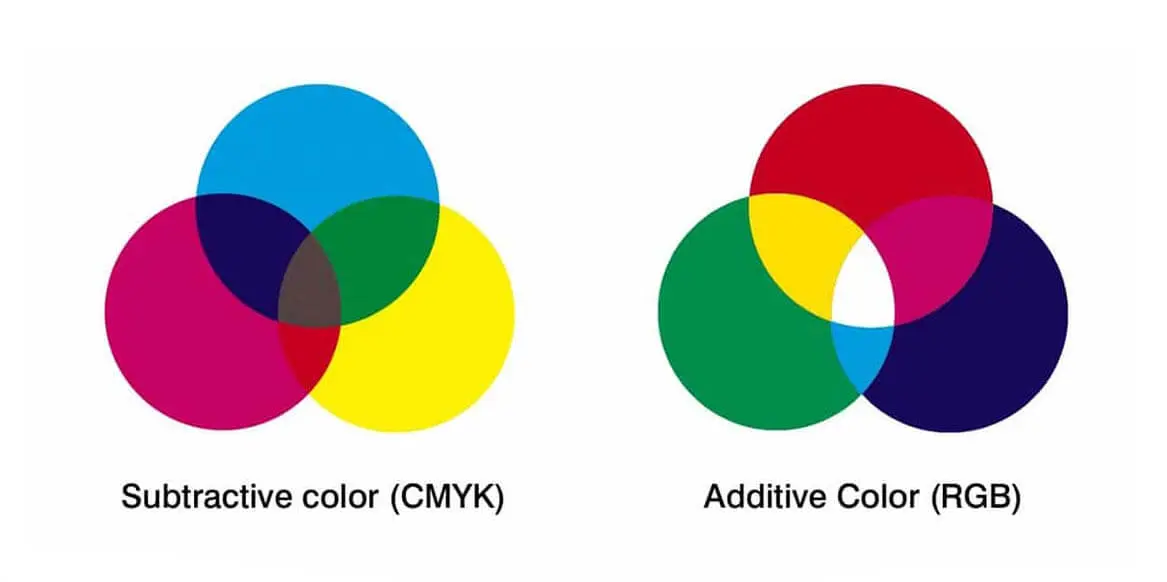

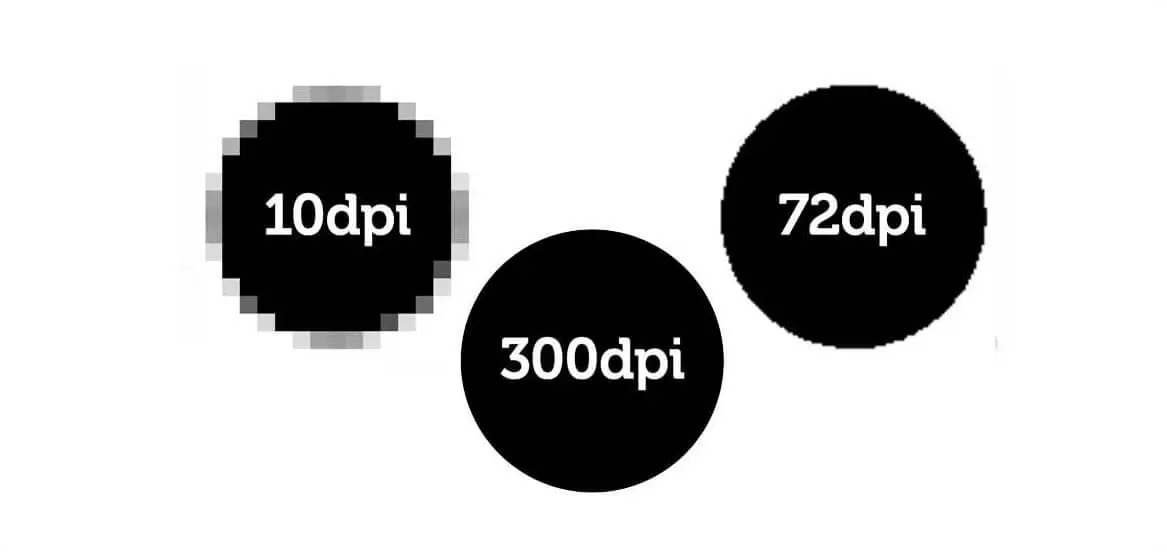

Here at Zunhao, we’re dedicated to ensuring your packaging pouches are printed with precise colors, logos, images, and designs exactly as you envision. Before production begins, we use the approved design (mutually agreed upon by you and us) to create sample products for your final confirmation.

If you’re not experienced in graphics, don’t worry—we’re here to assist you every step of the way. Below is a checklist outlining what you should consider when ordering custom printed packaging pouches, covering everything you need to know about artwork preparation.